Freezes are part of North Texas life, but freeze damage doesn’t have to be. A little prep now—plus a solid plan for power outages—can save you thousands and weeks of downtime when you want your pool ready for spring.

Texas Freeze Playbook: How to Protect Your Pool Equipment Before the First Hard Freeze

Blog/ Texas Freeze Playbook

Texas Freeze Playbook: How to Protect Your Pool Equipment Before the First Hard Freeze

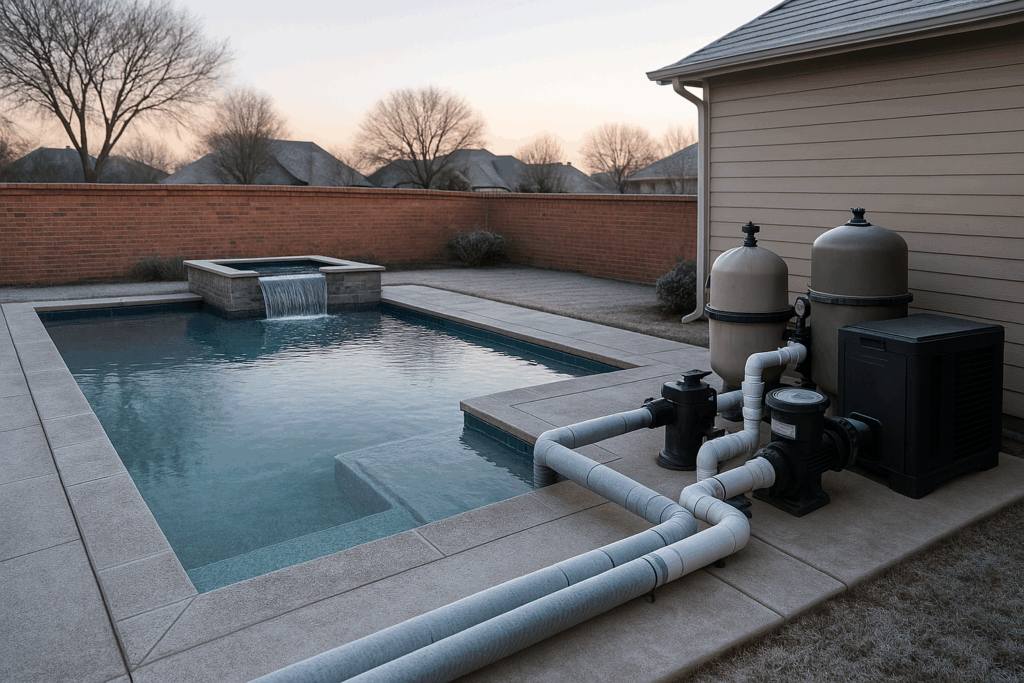

North Texas winters can flip from sunny to sub-32°F overnight. When that first hard freeze hits, pumps, filters, heaters, and PVC lines are at risk—especially if the power blips. This quick, homeowner-friendly playbook shows exactly how to prep your pool in Wylie (and around DFW) so you avoid cracked housings, burst pipes, and a green recovery in spring.

Why Freezes Break Pool Systems

When water sits still and freezes, it expands. That pressure can:

- Crack pump and filter housings

- Split PVC at fittings and valves

- Damage heater manifolds and salt cells

- Pop off pressure gauges and unions

Movement is your friend in a freeze; still water is what causes damage.

Two Weeks Before the First Freeze: Set Your System Up to Win

1) Book a quick inspection (or do a DIY check).

Confirm there are no slow leaks, drip joints, or air leaks on the suction side. Small problems become big—and expensive—when temps drop.

2) Clean + baseline your system.

- Empty skimmer and pump baskets

- Backwash/clean the filter

- Verify pressure is normal after cleaning

- Inspect O-rings and gaskets (lubricate or replace)

3) Confirm “freeze protection” settings.

Most automation and smart controllers can auto-run the pump at ~36–38°F. Make sure it’s enabled and that the temperature sensor reads accurately.

4) Wrap exposed plumbing.

Foam pipe wrap and insulated faucet covers on exposed PVC, heater unions, and valves help a ton. Don’t block required heater ventilation.

5) Consider a variable-speed pump runtime plan.

Program a low RPM you can bump up during freeze alerts. (If your pump is single-speed, plan to run it continuously on freeze nights.)

6) Stock the basics.

Foam wrap, union plugs, extra O-rings, zip ties, duct tape, granular shock or liquid chlorine, and a simple battery work light.

Want this handled for you? Our Pool Service team can winter-prep your equipment and dial in your automation so it’s set-and-forget.

48–72 Hours Before a Forecast Freeze

1) Balance your water.

Aim for proper pH/alkalinity and bump free chlorine to the high end of the safe range. Cold chemistry moves slowly—start clean.

2) Clear debris.

Skim leaves, empty baskets, and brush steps/corners. Debris steals chlorine and clogs skimmers right when you need flow most.

3) Verify valves and water features.

Set valve positions so water will circulate through all above-grade lines. If you have raised spas, sheer descents, or bubblers, plan how you’ll run them to keep those lines moving.

4) Test your freeze mode.

Force a manual “freeze protect” run to make sure the pump actually spins up and water is moving across every exposed run.

The Night Before / Day Of the Freeze

1) Run the pump continuously.

If you have automation, it’ll trigger automatically. If not, switch to manual and keep it on.

2) Open the spa spillway (if applicable).

Allow a gentle spill to keep that line turning. Don’t blast at full tilt if wind chill is extreme—just enough movement to prevent ice.

3) Insulate the equipment pad.

Add foam covers to exposed pipes/valves and drape a breathable blanket or tarp as a wind break around the pad (leave heater vents clear).

4) Salt systems.

Most salt chlorinators shut down in cold water; that’s normal. Turn the cell output down/off and use liquid chlorine as needed.

What to Do If the Power Goes Out During a Freeze

Movement stops, so act quickly to avoid breakage:

- Kill the breaker to the equipment to prevent a dry start later.

- Open the air relief on the filter (top) to break vacuum.

- Drain the pump (remove drain plugs) and remove the pump lid so trapped water can expand safely.

- Drain the filter (drain plug at bottom).

- Open heater drain plugs and union caps to let water escape; cover the heater body from direct wind (don’t block vents).

- Open low-point unions on exposed lines, if accessible, to let water trickle out.

- Turn off autofill to avoid adding fresh (freezable) water to static lines.

When power returns, reinstall plugs/lids, prime the pump with water, and restore normal flow. If you hear grinding, see leaks, or can’t prime, cut power and call a pro.

Emergency help needed? We handle freeze-related equipment repair and replacements. Tap Equipment Repair & Upgrades for priority service.

After the Freeze: Recovery Checklist

- Inspect for new drips, wet pads, or air in the pump basket (cloudy, frothy water).

- Check filter pressure; large jumps can indicate internal damage or ice-packed debris.

- Look for cracks on pump housing, heater unions, and salt cell bodies.

- Re-balance chlorine and pH; brush and vacuum any algae or silt that settled during long runtimes.

- If your salt system was off, resume normal chlorination once water temps are back up.

When to Call Diamond Sparkle Pools

Call our team if you notice:

- The pump won’t prime, screeches, or leaks at the seal

- Persistent air bubbles at returns (possible suction leak or crack)

- Filter pressure won’t stabilize, or there’s water weeping from the tank seam

- Heaters showing error codes after a freeze

- White salty crust on unions/salt cells (post-freeze seepage)

We’ll troubleshoot, repair or replace damaged components, and get your system stable fast—before small issues snowball into a springtime remodel.

Add a Simple Upgrade for Next Time

A few modest upgrades dramatically reduce freeze risk and stress:

- Variable-speed pump with robust freeze mode

- Pad re-plumb to minimize exposed vertical runs

- Automation + temperature sensor you can monitor from your phone

- Insulated equipment pad wind screen (vent-safe)

- Check valves on raised features to keep lines primed

Ask about bundling these with our Pool Service visit so you’re ready for the next front.

Final Word

Frequently Asked Questions

Do I need to drain the pool?

No. In-ground pools are fine left full. Keeping water circulating is the priority.

Is a cover required?

Not mandatory, but a mesh or safety cover can cut debris and wind chill over the water. Do not rely on a cover alone—keep water moving.

Can I just run the spa?

Keep the entire system circulating if lines/equipment are shared. Only isolating the spa can leave pool lines vulnerable.

Will automation save me every time?

Automation helps—but sensors can fail and power can drop. Have a no-power plan and the basic tools on hand.